Mobile Data Logger

Tofaş Türk Otomobil Fabrikası A.Ş opted to work with Technology Integration on this project for price competitiveness, the compact size and the reliability of the cRIO industrial controller, and the flexibility in the development of the user interface and test application.

The application consists of developing a mobile data logger, that monitors and logs signals from different types of sensors including ECU data from high speed and low speed CAN ports. The system is supplied with batteries in order to perform the tests while the car is moving.

Technology Integration developed the system utilizing NI’s Industrial Controller, MXIe 14 Slot Reconfigurable RIO Chassis, LX85 FPGA Chassis, LabVIEW, LV RT, LV FPGA, and DSC toolkits.

System Description:

Signals:

The system consists of 8 Temperatures signals, 4 Voltage signals, 4 Current signals, 2 Motor Speed signals, 1 Torque signal, 1 inclination signal, 1 frequency signal, and 2 CAN ports (High and Low).

Software:

The software of this application was developed to monitor and log the signals from the different sensors connected to different points in the vehicle and the ECU data from high speed and low speed CAN ports. The software also enables the user to log alarms and generate reports.

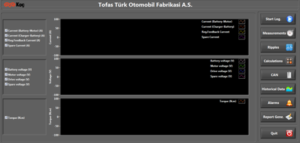

The software was divided into seven main parts (pages) which are, Measurement Page, Ripples Page, Calculations Page, CAN Page, Historical Page, Alarms Page and Report Generation Page.

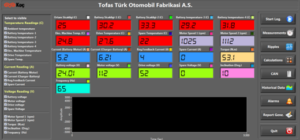

Measurement Page:

The Measurement Page shows the readings of all the sensors. The user can select which reading to show or hide according to the test he wants to run.

Ripples Page:

From the Ripples page the user can see the ripples of the Voltage signals, Current signals and Torque signal. The user can select any or all of these signals to display their ripples on the given chart.

Calculation Page:

All the Calculated readings from the voltage and current signals (such as, Electric power, electric Energy … etc.) are shown on this page.

CAN Page:

This page consists of two tree indicators; the fist tree is for the CAN LOW and the other tree is for the CAN HIGH. Both trees continuously display all the messages that are read from the two CAN ports (low and high).

Historical Data Page:

The user can retrieve all the historical data for each test performed in the past. The user can select the test and the signals he wants to retrieve and show their historical data.

Alarms Page:

The Alarms page shows all the current active alarms; from this page the user can configure the alarms levels for all signal.

Report Generation Page:

The user can generate custom reports for each test; he can select which signals to include in the test and send the generated report by email if he wants to.

Advantages:

• The Ability to perform the test while the car is moving;

• The ability to perform custom tests;

• Deterministic operation using a Real Time OS and FPGA;

• Simple and user friendly HMI;

• Configurable alarms;

• Easy to log and retrieve Data;

• Customizable reports;

• Expandable I/O modules;

• Multi level security system.