Controlling Paraffin Process

The National Chlorine Company selected Technology Integration to do this application for price competitiveness, the compact size of the compact FieldPoint controller, the simplicity of the graphical representation of the process and the unlimited number of PID loops that can be used since there is no need to have any specific hardware to build the PID loops; all the PID loops were built using LabVIEW software.

The system consists of 60 Analog Inputs, 16 Analog Outputs, 12 Digital Outputs and 64 Digital Inputs. The Control System was developed using National Instruments LabVIEW along with a real time Compact FieldPoint controller.

The application contains 15 PID control loops, with the ability to switch the output control between Automatic and Manual in a bumpless way.

The software of this application was developed to control the process, monitor the readings and log all the needed data in the historical database. The software was divided into four main parts (pages) as follows:

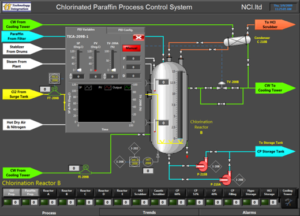

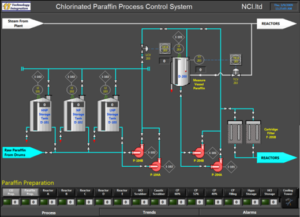

Process Control Page:

It contains 15 pages; each page graphically represents the actual process that has all the indicators that show the current reading of the analog input signals. Also, the user can see and change the parameters of the PID control loops.

Configuration Page:

From this Page the user can set and change the scaling of the analog inputs, disable/enable the alarms, change the alarms level, change the PID loop parameters, and disable/enable interlocks.

Trends Page:

This Page contains the Trend graph from which the user can show the trends of all the tags in the process.

Alarms Page:

In this page, the user can see the current alarms and all the historical alarms.

The combination of LabVIEW and Compact FieldPoint can give the following advantages:

• Simple and user friendly HMI

• Easy to change the configuration of the Scaling, Alarms, PID, and Interlocks parameters.

• Easy to maintain

• Easy to expand

• Unlimited number of PID control loops

• Automatic/Manual switching in a bumpless way

• Multi level security system

• Graphical representation that reflects the actual process